Economics of Big Wind

Note: This is an OCR of : VOLUME 5:

http://www.lifeofthelandhawaii.org/2009-0162%20Vol%205.PDF

The economic comparison section pages 289-313

OCR introduces many spelling errors in converting an image to text.

This document was filed by HECO 9 months after the filing deadline

I. Introduction

There is no single renewable energy resource capable of providing a “silver bullet” hedge against oil price volatility. As a result, meeting Hawaii’s aggressive renewable portfolio standards (“RPS”) will require the addition of multiple renewable energy resources into the Hawaiian Electric Companies’ systems. For the island of Oahu, Big Wind^ has been shown to be a reasonable cost-competitive renewable energy resource option for meeting the Companies’ RPS goals, with the added benefit of being commercially available on a large scale with no fuel costs. And although there does not appear to be any other single renewable resource alternative comparable (in cost and capacity) to the Big Wind resource for Oahu, Hawaiian Electric is currently pursuing a number of diverse renewable energy alternatives which, in tandem with Big Wind, could help contribute to Hawaii’s fossil-fuel independence.

As further discussed below, the degree of evaluation differs for the various alternatives. The costs of some alternatives have already been formally determined (e.g., costs for distributed photovoltaic (“PV”) resources that are included in the Company’s feed-in tariffs (“FIT”)). The costs of other alternatives have only been evaluated at a high level, but are being more formally analyzed in connection with other initiatives (e.g., concentrated solar power (“CSP”)). In still other instances, large-scale evaluations of certain renewable resources have not been conducted due to the currently limited nature of such resources (e.g., the lack of biomass fuel stock in Hawaii to support large-scale generation).

The sections that follow document the evaluation considerations over the course of the Stage 1 Studies, including costs and availability of alternative resources. As the modeling and analyses progressed, the newly attained insight was used to build upon other aspects of the studies and/or update previous assumptions. As a result, there is an iterative progression to the cost evaluations (in Part II and Part IV, below) conducted over the course of the Stage 1 Studies. A preliminary, high-level comparison (referred to as a “pre-modeling” comparison) of the cost for wind and solar technologies needed to generate an equivalent amount of energy was conducted prior to the completion of the Stage 1 Studies modeling work performed by General Electric (“GE”). Part II summarizes (1) this pre-modeling comparison of the cost of 400 megawatts (“MW”) of Big Wind to an all solar PV alternative (using an equivalent energy production of 1,051 gigawatt-hours (“GWh”) per year as a basis of the comparison), (2) an updated cost evaluation that factors in the results of Stage 1 Studies modeling work performed by GE, and (3) additional evaluations. Part III discusses the Companies’ efforts to investigate and pursue other viable renewable alternatives in Hawaii. Part IV compares the cost of an inter- island Big Wind scenario using results from the scenario modeling analysis against the costs of various other resource portfolios where different renewable resources were used in place of Big Wind to meet the Companies’ RPS goals.

II Big Wind vs Large Scale Solar

The Company’s preliminary, pre-modeling comparison of the cost of 400 MW of Big Wind to an all solar PV alternative was conducted in recognition that only two renewable technology alternatives for Oahu – wind and solar – are anticipated to be commercially available on a large scale within a reasonably near term and with no fuel costs. From a comparative cost standpoint, wind is the preferred resource and Big Wind is a cost competitive option for developing that resource.

A.Pre-Modeling Evaluation

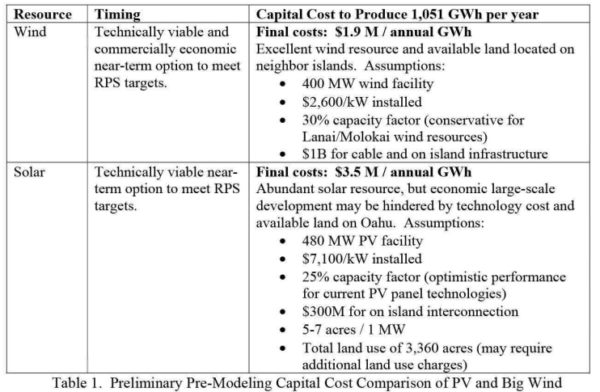

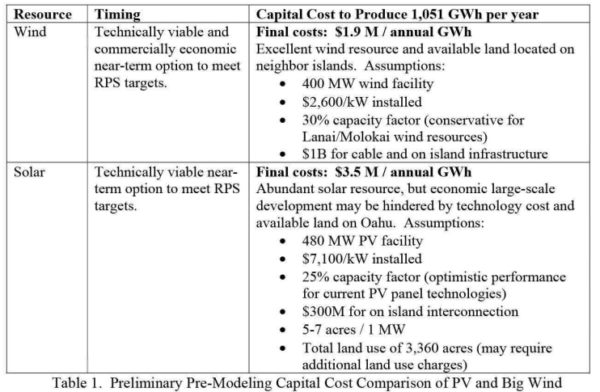

The economic viability of Big Wind as opposed to relying solely on on-island PV resources was addressed as part of a high-level, pre-modeling, evaluation process in the Stage 1 Studies. To understand the cost impacts of various technologies, this high-level cost analysis, as provided in the Company’s Reply SOP (page 15) and response to PUC-IR-3 (page 4), compared the costs for wind and solar technologies needed to generate an equivalent megawatt-hour (“MWh”) amount of energy. This comparison approach considered the energy production of wind and solar technologies as represented by their energy-based capacity factors, land use differences (in acres), cost of interconnecting infrastructure, and installed cost per kilowatt (“kW”) of the solar mid wind plant facilities.

As shown in Table 1 below, a conservative (low) 30% net capacity factor^ was assumed for a 400 MW off-Oahu wind project, resulting in an annual energy production of 1,051 GWh (0.30 X 8,760 hrs x 0.400 GW). While wind resources on the islands of Molokai and Lanai are estimated to be able to produce a far greater amount of energy per year, from mi economic standpoint, the pre-modeling evaluation used a reduced energy based net capacity factor as some level of excess energy curtailment was expected. In comparison, a generous (high) 25% energy based capacity factor was assumed for PV technologies located on Oahu. Table 1 summarizes this preliminary comparative approach for wind versus PV resources assuming 1,051 GWh of energy production as the equivalent comparison metric for calculating the associated assumed cost of each technology.

Assuming a preliminary inter-island cable system cost of $700 million, Oahu on-island infrastructure cost of $300 million, and commercial wind power facilities cost of $2,600/kW (adjusted for higher development costs in Hawaii), the pre-modeling compmison resulted in a capital cost of approximately $1.9 million/GWh to generate and deliver 1,051 GWh annually from the 400 MW neighbor-island wind plant.

In order to produce the same energy output of 1,051 GWh from a PV facility on Oahu (assuming a 25% capacity factor), a 480 MW PV facility would need to be built. Such a facility would require approximately 3,360 acres of land on-island (480 MW x 7 acres/MW). A facility of this size would be roughly equal in acreage to 32 football stadiums the size of Aloha Stadium (approximately 104 acres), and larger than the entire Kaneohe Marine Corps Base Hawaii (approximately 2,951 acres). The pre-modeling comparison results indicate that assuming on-island interconnection costs of approximately $300 million and current costs for commercial-scale PV of $7,100/kW, the capital cost to generate the 1,051 GWh annually from solar PV resources would be approximately $3.5 million/GWh, not including any land costs. The preliminary pre-modeling comparison illustrated that it would not be economically viable to pursue a PV-only solution on Oahu due to the high cost of PV project development and the feasibility of neighbor island wind development. Based on this comparative cost analysis the Company further evaluated the development and interconnection of large-scale neighbor island wind resources to the Oahu grid.

B. Stage 1 Implementation Studies Results

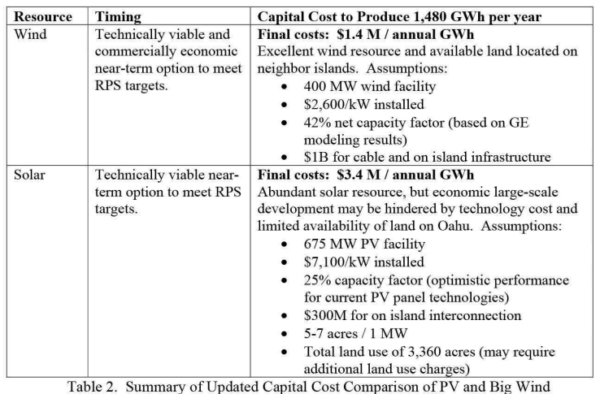

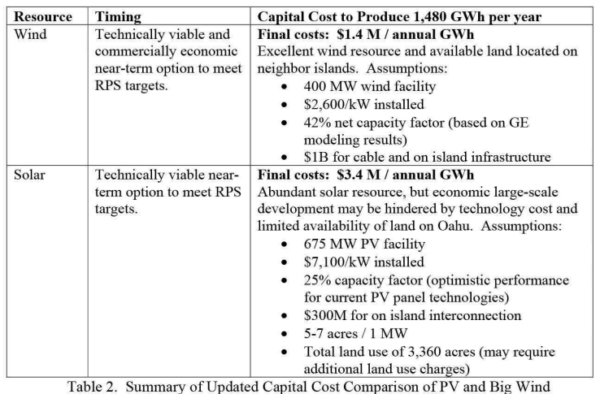

As noted above, the Company’s pre-modeling evaluation of the economic viability of Big Wind assumed a conservative net capacity factor of 30%, yielding an annual wind energy production of 1,051 GWh. However, upon completion of the Stage 1 Studies modeling work performed by GE, the pre-modeling cost evaluation was updated. More specifically, the GE modeling work concluded that a net capacity factor of approximately 42% was reasonably achievable for the 400 MW Big Wind projects, provided that certain operational strategies, system enhancements and wind plant capabilities can be implemented with resulting reduction in the magnitude of curtailed excess energy. Applying the modeled net capacity factor of 42% for Big Wind in place of the original 30% assumption, 1,480 GWh of wind energy could be harnessed and delivered annually from 400 MW of neighbor-island wind. The results of the studies indicate that the net capacity factor for the Big Wind Projects can be significantly increased, thus reducing the per kWh price of the wind energy, and making the projects more attractive from an economic standpoint.

Table 2 summarizes the update of the preliminary comparative approach for wind versus PV resources applying the 1,480 GWh of projected annual wind energy production (i.e., 42% net capacity factor = 1,480 GWH / (8,760 hrs x 0.400 GW)) derived from the GE modeling work as the equivalent comparison metric for calculating the associated assumed cost of each technology.

Hawaiian Electric has worked with its consultant, Papay Quayle Resources, LLC to conduct an economic sensitivity analysis of the cost of Big Wind. As summarized in Table 3, for 1,480 GWh per year of wind energy delivered to Oahu (42% net capacity factor), the LCOE values derived in that analysis are summarized for various Big Wind project components based on the assumptions listed below.

2.National Renewable Energy Laboratory

Additional economic evaluations were independently conducted by the National Renewable Energy Laboratory (“NREL”), using NREL’s economic database/assumptions to assess the business case for building 400 MW of neighbor-island wind. NREL’s preliminary findings were presented to the Technical Review Committee (“TRC”) for the Stage 1 Studies in May 2010. The findings of the evaluations showed that solar technologies (e.g., concentrated solar power, PV-tracking, PV-fixed distributed, PV-fixed utility-scale) were more expensive than wind technologies in terms of levelized cost of energy (“LCOE”), and more costly in terms of capital expenditures. The results of the evaluation were summarized in the NREL presentation, ‘^Hawaii Big Wind/Undersea Cable Economic Analysis” that was presented to the TRC.

3. Land Use Considerations

In order to achieve 1,480 GWh of annual solar generation, roughly 4,800 acres would be needed to site the single-axis tracking PV technologies necessary to generate 682 MW (assuming seven acres/MW). Figure 1 below depicts how much land 4,800 acres covers when overlaid on

Additional discussion regarding the challenges associated with siting PV installations on Oahu is provided in Section IV.A, below. Based on the Big Wind Stage 1 Studies, even with the complexity of developing an inter-island cable interconnection, harnessing wind resources from Molokai and Lanai appears to be a viable and cost-competitive option for reducing Hawaii’s dependence on imported fossil fuels in comparison to a PV-only development solution on the land-constrained island of Oahu.

III. Other Options Being C^onsidered under a Portfolio Approach

In addition to the Big Wind Studies, other initiatives that the Hawaiian Electric Companies are pursuing or have pursued to investigate viable renewable energy resource alternatives include the following:

Concentrated Solar Power

Hawaiian Electric is investigating the development of CSP technologies where appropriate. Land space and cooling water constraints may limit wide-spread CSP options on Oahu. In addition, Hawaii’s moderate solar climate, with frequent obscuration from passing clouds, may also limit the viability of CSP technologies. In 2009, Hawaiian Electric submitted an application to the U.S. Department of Energy (“DOE”) pursuant to the American Recovery and Reinvestment Act of 2009 to investigate the feasibility of using CSP to augment baseload generation or to provide a thermal source that replaces the use of conventional generation (application DE-FOA-104). The application advanced to a second round of consideration but, due to the limited scale of the application, the proposal was not funded. Nonetheless, the Company continues to collaborate with the Electric Power Research Institute on a solar assessment project to evaluate PV and CSP potential at the Company’s Kahe Power Plant site.

Distributed Generation

Analogous to the Company’s use of and experience with substation distributed generation (“DG”) to meet load demand, the Company is developing capabilities to more effectively evaluate the impacts of smaller DG and high-penetration PV on distribution circuits.

OTEC

The Company is monitoring and encouraging the development of proposed ocean thermal

energy conversion (“OTEC”) projects. The proposed technologies have yet to be demonstrated on a commercial scale.

Alternative Fuels

Hawaiian Electric is investigating the viability of the inclusion of alternative fuels mid the conversion of some of the Company’s steam generating units to utilize biofuel. Hawaiian Electric described, in its HECO T-8 testimony submitted in Hawaiian Electric’s 2011 test year rate case, the Company’s plans to convert up to four of its six generating units at Kahe Generating Station by 2015 in preparation for using biofuel blended with low-sulfur fuel oil (“LSFO”) in order to meet the RPS of 15% of net electricity sales from renewable energy by 2015. The amount of renewable energy from biofuel planned for 2015 will vary depending upon the timing of successful integration of other renewable energy projects.

Hawaiian Electric installed equipment at Kahe 3 to enable co-firing of biofuel with LSFO. This Kahe 3 Biofuel Co-firing Project successfully tested cofiring of biofuel in early 2011. The results of the test are being evaluated and the evaluation is expected to be completed in mid 2011. The project will evaluate generating unit operations and performance and fully characterize the environmental impacts of biofuel operation. A detailed program plan of the Kahe 3 Biofuel Co-firing Project was submitted with the Company’s application for approval to commit capital funds and for approval of the Biofuel Supply Contract costs in Hawaiian Electric’s Energy Cost Adjustment Clause in Docket No. 2009-0155. After evaluating the results of the Kahe 3 Biofuel Co-firing Project, Hawaiian Electric will identify the appropriate blend of biofuel that can be optimized to generate electricity for Kahe 3 and other generating units in its fleet. With the knowledge gained from the Kahe 3 Biofuel Co-firing Project, Hawaiian Electric will then prepare projects to install necessary co-firing equipment on other units beginning with Kahe 4, with the goal of having Kahe units 1 through 4 ready for biofuel utilization by 2015 and Kahe 5 and 6 before 2020. In addition to equipping the generating units to co-fire biofuel, Hawaiian Electric is plaiming for the fuel infrastructure required to receive, transport and store biofuels for use at the Kahe Generating Station.

Hawaiian Electric’s new CIP CT-1 generating unit will continue to operate using biodiesel. The experience Hawaiian Electric gains from implementing a biofuel blend at Kahe may serve to replicate a similar approach to integrating biofuel at the Waiau 7 and Waiau 8 steam units, the most efficient baseload units at the Waiau Generating Station. In addition, the Waiau 9 and Waiau 10 peaking units currently use diesel fuel and could potentially be converted to use biodiesel.

IV. Scenario Cost Analysis

In addition to the cost analyses described in Part II above, the Company conducted mi RPS analysis that compared the costs of Big Wind against other renewable resources in scenarios developed to meet the 2020 and 2030 RPS targets required by HRS § 269-91.(7) While independent of the Big Wind Stage 1 Studies, this high-level RPS analysis provided another sepmate assessment of the relative economic competitiveness of Big Wind using the results of the Stage 1 modeling effort (e.g., 42% net capacity factor for 400 MW of wind) against other scenarios to meet future RPS goals. The cost of the Big Wind scenario was compared to the cost of other scenarios that included different renewable resources in place of Big Wind. The relative cost differences between the scenarios provided another validation of the reasonableness of the Big Wind Implementation Studies costs as part of an overall portfolio-based approach.

A. Scenario Descriptions

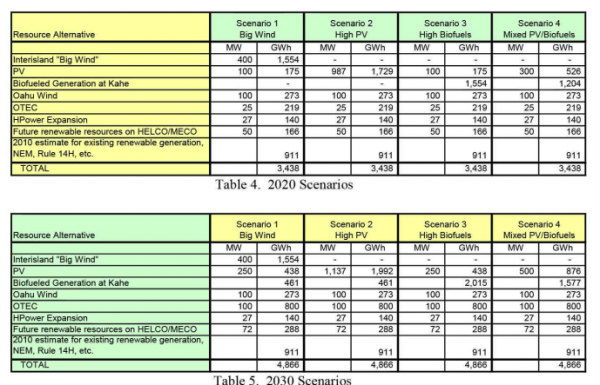

Four scenarios (different than the Big Wind Stage 1 study modeling scenarios) were evaluated in the RPS analysis:

Scenario I – “Reference Scenario” with 400 MW of Big Wind;

Scenario 2 – “High PV Scenario” with a high penetration of PV systems;

Scenario 3 – “High Biofuels Scenario” with a large volume of biofuels; and

Scenario 4 – “Mixed PV/Biofuel Scenario” with high penetration of PV and a large

volume of biofuels.

HRS § 269-93 permits the Hawaiian Electric Companies to aggregate their renewable portfolios to achieve the RPS, so assumptions were made as to what renewable energy contributions would be provided by HELCO and MECO, as well as assumptions for future renewable resources to be located on Oahu that will contribute to achieving the RPS. The following is a list of the renewable energy resources assumed mid included equally in all four scenarios:

All existing renewable energy generation resources (e.g.. Net Energy Metering, existing H-Power, etc.) from the Hawaiian Electric Companies were represented using 2010 RPS actual outputs (911 GWh) and represented as constmit for the 2020 target and 2030 target;

- 50 MW of new renewable resources represented at HELCO and MECO to achieve the 2020 target, and increased to 72 MW for 2030 to represent additional renewable energy added to the systems (such as new wind farms and PV systems);

- 100 MW of wind at Hawaiian Electric (representing 30 MW from the newly installed Kahuku wind farm and 70 MW from potential future wind farms on Oahu);

- 27 MW of additional waste-to-energy representing the expansion of H-Power; and

- 25 MW of OTEC in 2020, and increased to 100 MW for 2030.

The RPS analysis does not include a comparison of costs associated with the renewable resources assumed to be common in all of the scenarios, as the analysis is focused on comparing the cost differences between the differentiating components of each scenario and treating any common costs the same across all of the scenarios.

Scenario 1

Scenario 1, or the Reference Scenario, reflects the case with 400 MW of Big Wind supplying power to Oahu via an undersea cable connecting the Lmiai and Molokai wind plants to Oahu. In Scenario 1, the Company assumed the smne 1,480 GWh of delivered wind energy on Oahu as was assumed in Section II.B above, which equates to 1,554 GWh of energy output at the wind farms after accounting for 5% in transmission losses. Consistent with the assumptions in Table 3 above, the Company assumed a levelized T&D infrastructure cost of l.lp/kWh and a levelized undersea cable cost of 6.87^/kWh. For the low cost reference sub-scenario, it assumed a purchase price of 11^/kWh for the levelized cost of wind energy. Based on these assumptions, the Company calculated the low levelized cost for the delivered wind energy to be 18.97p/kWh. For the high cost reference sub-scenario, the Company assumed a higher energy purchase price of 13^/kWh, based on the letter agreement between Hawaiian Electric and Castle & Cooke dated January 3, 2011. Based on this higher energy price assumption, the Compmiy calculated the high levelized cost for the delivered wind energy to be 20.97^/kWh.

While Hawaiian Electric has gained considerable insight for the development of an inter- islmid cable system, there remain project details that also need to be evaluated. Based on the preliminary economic evaluation, the inter-island cable project development cost may fall in a range from $800 million to over $1 billion, with approximately $340 million (levelized) in ongoing revenue costs. As the plmining for the inter-island cable system proceeds, appropriate project financing will need to be factored in depending on the entity building, owning and operating the cable infrastructure.

In the Energy Agreement, it was assumed that the State would conduct an RFP process to select an undersea cable developer, which would install an undersea transmission cable to be owned by the State. However, several important developments thereafter have led to the introduction of legislation that would facilitate a different regulatory structure under which the Commission would oversee certification of an independent transmission utility company to commercially develop, finance and construct undersea energy transmission cable systems. The completed undersea cable system would be owned and operated by the transmission utility (i.e., a certified cable company granted a certification of public convenience and necessity by the Commission after the completion of the RFP process), although Hawaiian Electric could eventually acquire the undersea cable, with Commission approval, sometime after commercial operations are achieved. To that end, the nem-term steps toward development of the Big Wind Projects are expected to include the conduct of a Commission-authorized RFP process resulting in selection of a proposed certified cable company and a proposed cable tariff in 2011-2012. In the meantime, the Companies have commenced the scoping of the Stage 2 Implementation Studies and plan to file an application to request deferral of the Stage 2 Implementation Studies costs at some point in the near future.

Scenario I also includes 100 MW of new PV resources in 2020 and 250 MW of PV in 2030. These new PV resources represent new residential rooftop and Imge-scale PV plants located on Oahu. The energy output from the PV resources was determined assuming that 50% of the PV systems were rooftop systems with a 17.3% capacity factor and the other 50% of the systems were tilted single-axis tracking systems with a 22.7% capacity factor or a composite average of 20% for all systems. The cost for all of the PV resources in all scenarios was assumed to be 23.60/kWh, which is the Companies’ FIT rate for Tier 3 PV projects that utilize the 24.5% refundable state tax credit. This resource cost was assumed to remain the same in both years 2020 and 2030. In 2030, 461 GWh of renewable generation produced using biofuels would also be required to meet the 40% RPS. This analysis used a low bio-crude price forecast value of $27.31/MBtu for the low cost sub-scenario and a high price forecast value of $39.71/MBtu for the high cost sub-scenario.

Scenario 2

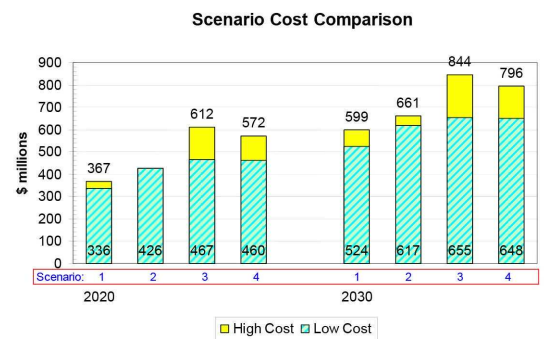

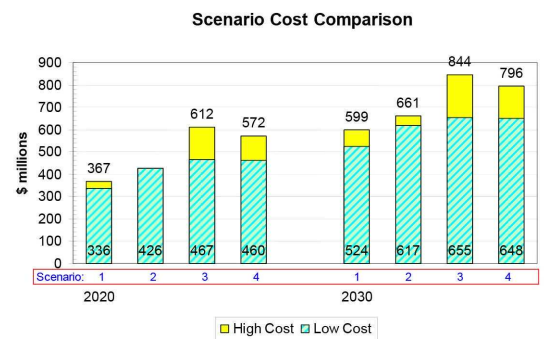

Scenario 2, or the High PV Scenario, assumed increases in the amount of PV resources in order to replace the Big Wind energy from Molokai and/or Lanai that was assumed in the Reference Scenario. For the year 2020 analysis, 987 MW and 1,729 GWh of PV energy were assumed to be included. Forthe year 2030 analysis, 1,137 M W a n d 1,992 GWh of PV energy were assumed to be included. The 2030 Scenario also included 461 GWh of renewable generation produced using biofuels (the same amount included in Scenario 1 for 2030). The analysis used a low bio-crude price forecast value of $27.31/MBtu for the low cost sub-scenario and a high price forecast value of $39.71/MBtu for the high cost sub-scenario. The cost of the energy from the PV resource was assumed at a FIT Tier 3 cost of electricity of 23.6^/kWh. The High PV Scenario also included a 1.10/kWh proxy adder for the T&D improvements needed to accommodate this intermittent resource (as discussed below), but assumed no additional costs to address the large land requirements, and no additional system operation costs (although it should be noted that the inclusion of the additional costs that would likely be required to address the land requirements and system operation needs would raise the cost of the PV resource). Under these assumptions, the Company calculated that using large amounts of PV (987 MW to 1,137 MW) to meet the RPS targets would cost roughly $426 million in 2020 and between $617 and $661 million in 2030.

Connecting large amounts of intermittent, as-available, renewable generating resources will challenge system reliability and power quality, and will require improvements in Hawaiian Electric’s Oahu T&D infrastructure as well as changes in system operations including spinning reserve levels. In order to make the High PV scenario more comparable to the Big Wind scenario, the analysis includes a levelized cost adder of 1.1^/kWh to account for the T&D improvements that will be needed to accommodate the large amounts of PV added to the system.

This amount is based on the T&D infrastructure cost developed to integrate the Big Wind power on Oahu and serves as a proxy cost adder for the T&D infrastructure to support the high PV levels. The Company realizes that the actual T&D costs could be higher or lower and that the impact to system operating costs will need to be studied. One such study, the Oahu Solar Integration Study, was initiated in March 2011 and will analyze the transmission system impacts of high penetrations of central station solar and distributed PV similar to the GE modeling studies performed for Big Wind. Key entities that participated in the prior GE modeling studies are also involved with the Oahu Solar Integration Study, including GE International, NREL, AWS Truepower, Hawaii Natural Energy Institute and the U.S. DOE, which is providing the majority of the funding for this study. The study is expected to be completed in late 2012. A similar study is being conducted for the MECO system.

Installing large amounts of distributed, rooftop PV also presents significant challenges. Even assuming that all of Hawaiian Electric’s approximately 250,000 customers have adequate rooftop space for installations of 2 kW PV systems on each roof (which is not a reasonable assumption due to factors restricting direct exposure to the sun),^” this would only result in approximately 500 MW of distributed, rooftop PV. It is therefore apparent that distributed, rooftop PV alone can not account for the large amount of PV that would be required.

Finding and acquiring large land parcels on Oahu, at a reasonable cost, necessary to install large-scale PV to generate the energy required in Scenario 2 (987 MW in 2020 and 1,137 MW in 2030) would also be extremely challenging. If all of the installed PV in Scenario 2 was assumed to come from large-scale PV installations, using five to seven acres of land per MW of PV, approximately 4,935 (987 MW x 5 acres/MW) to 7,959 (1,137 MW x 7 acres/MW) acres of land would be required. This is an extremely large amount of open land for Oahu. By way of comparison and as noted above, the Aloha Stadium parcel is 104 acres mid the size of Kaneohe Mmine Corps Base Hawaii, which occupies the entire Mokapu Peninsula, is 2,951 acres.

Hawaiian Electric recently executed its first two agreements to purchase power (“PPAs”) generated by utility-scale PV facilities. Although those PPAs are currently pending before the Commission, the independent power producers’ (“IPPs”) difficulties in siting their projects highlight some of the land use and permitting challenges that large-scale PV facilities also face on Oahu. For example, with respect to the Company’s 5 MW PV PPA with Kalaeloa Solar Two, LLC (“Kalaeloa Solm”), Kalaeloa Solar begmi with an agreement in concept with the State of Hawaii to lease state-owned land at the Kaleloa airport mid construct a commuter airplane shade structure on that land utilizing its PV panels as the shade structure. However, during the course of the final negotiations, Kalaeloa Solar notified Hawaiian Electric that the IPP was unable to reach an agreement with the State on terms of a lease for their proposed airport site due to restrictive leasing terms. As a result, Kalaeloa Solar was forced to relocate its project to a nearby subleased parcel of land owned by the Department of Hawaiimi Home Lands. Because the new pmcel was essentially a greenfield site, Kalaeloa Solar revised the design of its facility to a ground mounted tracking system. The smaller size of the new parcel also precluded Kalaeloa Solm from proceeding with its original proposal for a 17 MW facility. The Company’s other pending PV PPA is for a 5 MW facility with IC Sunshine LLC (“IC Sunshine”), and there have been siting issues with that project as well. For example, although the term of the IC Sunshine PPA is for 20 years beginning on the project’s in-service date, the IPP to date has only been able to secure a ground lease and grant of easement for the project’s Campbell Estate Industrial Park site until March 31, 2024 (which is roughly half-way through the term of the PPA).[12]

Notably, the amount of power to be provided by the Kalaeloa Solar and IC Sunshine facilities only adds up to 10 MW of PV generation. Achieving 1,137 MW of PV generation from projects of this size would require approximately 227 facilities. The Company’s “High PV” scenario conservatively assumes that additional PV facilities would entail the same level of siting costs. Presumably, however, given the limited supply of available sites and the preference of IPPs to save on siting costs by starting with the lowest “hanging fruit,” the sites that are chosen emlier in the process should be among the cheapest and easiest to develop. As suitable sites become more scarce, it is reasonable to assume that the siting costs that are factored into the PPA pricing will increase (although such increases may be offset to some extent by future decreases in the cost of PV technologies). In contrast to the issues associated with siting multiple PV projects on Oahu , the Big Wind initiative is a single project with large sites on the neighbor islands.

Scenario 3

Scenario 3, or the High Biofuels Scenario, assumed the use of biofuels in Hawaiian Electric’s Kahe units in order to replace the Big Wind energy from Molokai and/or Lanai that was assumed in the Reference Scenario. Scenario 2 also includes 100 MW of new PV resources in 2020 and 250 MW of PV in 2030 at 23.6 cents/kWh as discussed in Scenario 1 above. For the year 2020 analysis, 1,554 GWh of biofueled energy was assumed using a low bio-crude price forecast value of $27.13/MBtu for the low cost sub-scenario and a high price forecast value of $36.39/MBtu for the high cost sub-Scenario. For the year 2030 analysis, 2,015 GWh of bio- fueled energy was required to meet the 40% RPS with the cost range for this energy in 2030 valued using a low bio-crude price forecast value of $27.31/MBtu for the low cost sub-scenario and a high price forecast value of $39.71/MBtu for the high cost sub-scenario. Under these assumptions, the Company calculated that the annual cost using Imge amounts of biofuels in 2020 to meet the RPS targets would range between $467 million under the low cost sub-scenario and $612 million under the high cost sub-scenario. For the year 2030, the Company calculated this cost range to be between $655 million and $844 million for the low and high cost sub- scenarios, respectively.

It should be noted that the capital and O&M cost impacts to use biofuels in the Kahe units were not included in this scenario analysis. Inclusion of these costs would raise the cost of the biofuel generation resource in the Scenarios where biofueled generation is included.

Scenario 4

Scenario 4, the Mixed PV/Biofuel Scenario, assumed a combination of PV resources mid renewable generation produced by the use of biofuels in order to replace the Big Wind energy from Molokai and/or Lanai that was assumed in the Reference Scenario. For the year 2020 analysis, 300 MW and 526 GWh of PV (evaluated at an energy cost of 23.6 p/kWh), and 1,204 GWh of generation produced from using biofuels in the Kahe units were assumed. For the year 2030 analysis, the assumed resource mix included a growth of the PV resources to 500 MW and 876 GWh (evaluated at the FIT Tier 3 energy cost of 23.6e/kWh), and 1,577 GWh of generation produced from using biofuels in the Kahe units to meet the 40% RPS target. As discussed above, coimecting large amounts of renewable generating resources will require improvements in Hawaiian Electric’s Oahu T&D infrastructure. Thus, like Scenario 2, the cost of the PV resource in Scenario 4 also includes a levelized cost adder of 1.10/kWh to account for the T&D improvements that will be needed to accommodate these large amounts of PV. Like Scenario 3, the cost of the biofueled energy in 2020 was calculated assuming a low bio-crude price forecast value of $27.13/MBtu for the low cost sub-scenario and a high price forecast value of $36.39/MBtu for the high cost sub-Scenario. For the year 2030, the cost range for this energy in 2030 was calculated (as in Scenario 3) assuming a low bio-crude price forecast value of $27.31/MBtu forthe low cost sub-scenario and a high price forecast value of $39.71/MBtu for the high cost sub-scenario. Under these assumptions, the Company calculated that in 2020, using the PV/Biofuel mix in Scenario 4 to meet the RPS targets would range in cost between $460 million under the low cost sub-scenario and $572 million under the high cost sub-scenario. For the year 2030, the Company calculated this cost as ranging between $648 million for the low cost sub-scenario and $796 million for the high cost sub-scenario.

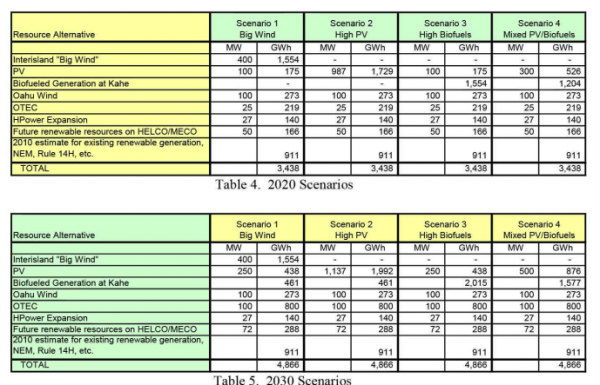

The renewable energy resources for the scenarios are summarized in Table 4 and Table 5

below, for 2020 and 2030, respectively:

Scenario Results

Using the assumptions outlined in each scenario, the annual cost of each scenario was calculated as shown below in Table 6. The results of the analysis indicate that Scenario 1, the Big Wind scenario, has the lowest annual cost in the year 2020 ($336 to $367 million) and in the year 2030 ($524 to $599 million) as compared to each of the other alternative scenarios (2, 3 and 4) evaluated. These comparative costs show that Big Wind is a viable and cost-competitive option to attain RPS goals.

Big Wind (Scenario 1) is lower in annual costs relative to High PV (Scenario 2) to produce renewable generation to meet the RPS goals. Based on the assumptions used in Scenario 2 above, the calculated cost of the renewable electrical energy used to meet the RPS for 2020 for the High PV scenario ($426 million per year) is about 27% greater than the low-end cost calculation of Big Wind ($336 million per year) and about 16% greater than the high-end cost calculation of Big Wind ($367 million per year). For 2030, the High PV low-end cost calculation ($617 million per year) is about 18% greater than the Big Wind low-end cost calculation ($524 million per year); and the High PV high-end cost calculation ($661 million per year) is 10% greater thmi the Big Wind high-end cost calculation ($599 million per year).

Big Wind (Scenario 1) is also lower in annual costs relative to the High Biofuels (Scenario 3) under which biofuels are used in the Kahe boilers to produce renewable generation to meet the RPS goals. Based on the assumptions used in Scenario 3, in 2020, the low-end calculated cost for Scenario 3 ($467 million per year) is 39% greater than the Big Wind low-end calculated cost; and the high-end calculated cost for Scenario 3 ($612 million per year) is 67% greater than the Big Wind high-end cost calculation. In 2030, the low-end calculated cost of Scenario 3 ($655 million per year) is 25% greater than the Big Wind low-end calculated cost; and the Scenario 3 high-end calculated cost ($844 million per year) is 41% greater than the high- end cost calculated for Big Wind.

Scenario 4, which represents a combination of PV resources and renewable generation produced by the use of biofuels, also results in higher annual costs compared to the Big Wind costs of Scenario I. Based on the assumptions used in Scenario 4, in 2020, the low-end calculated cost for Scenario 4 ($460 million) is 37% greater than the Big Wind low-end calculated cost; and the high-end calculated cost for Scenario 4 ($572 million per year) is 56% greater than the Big Wind high-end cost calculation. In 2030, the low-end calculated cost of Scenario 4 ($648 million per year) is 24% greater than the Big Wind low-end calculated cost; and the Scenario 4 high-end calculated cost ($796 million per year) is 33% greater than the high- end cost calculated for Big Wind.

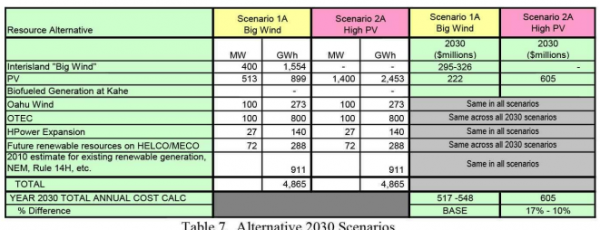

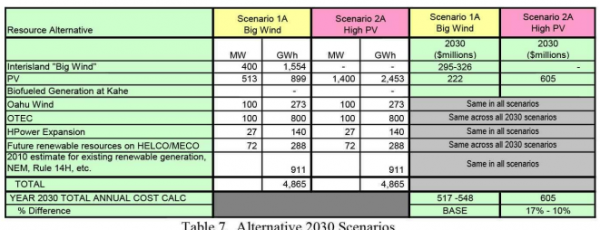

C. 2030 Alternative Scenario Analysis

Two alternative scenarios (see Table 7) were developed for the year 2030 to show how Scenario 1 (Big Wind) and Scenario 2 (High PV) would compare if the biofuel energy component was not included in the portfolio to meet the 2030 RPS goal. Scenario 1A was developed assuming a higher amount of PV (increased from 250 MW included in Scenario 1 to 513 MW), in addition to the 400 MW of Big Wind energy. Thus, 899 GWh of PV energy was assumed in Scenario IA. In Scenario 2A, an even higher amount of PV was assumed: 1,400 MW and 2,453 GWh of PV. These two additional Scenarios represent portfolios where intermittent resources are assumed to supplement the other renewable resources common in all scenarios to meet the RPS goal. As discussed previously, connecting large amounts of intermittent, as-available, renewable generating resources will challenge system reliability and power quality, and will require improvements in Hawaiian Electric’s Oahu T&D infrastructure as well as changes in system operations including spinning reserve levels. A comparative cost analysis of these two alternatives further confirms that Big Wind is a viable and cost-competitive option to attain RPS goals. The annual cost of the alternative High PV Scenario 2A ($605 million) is 17% higher than the Scenario IA low-end minual cost estimate of Big Wind ($517 million per year) and about 10% greater than the high-end cost calculation of Big Wind ($548 million per year).

D. Scenario Analysis Conclusions

The RPS scenario analysis shows that the Big Wind resource is a reasonable mid cost competitive alternative relative to other renewable resource options that could be used to meet the required RPS goals. In all comparisons, the Big Wind scenario was the lowest cost option,as shown in Figure 2, below.

The RPS scenario mialysis also demonstrates how using renewable energy generated from biofuels can be an important element to make up any shortfalls in meeting the RPS targets. While the exact amount of biofuels that will be needed is uncertain, Hawaiian Electric’s planned conversion of its Kahe generating units to bum bio-crude blends will provide essential flexibility to address RPS renewable generation energy shortfalls which may arise if any of the numerous renewable energy resources or projects are delayed or do not materialize.

Integrating renewable and sustainable biofuels into a portion of the Companies’ existing generating systems is an important part of the Companies’ renewable energy strategy of delivering clean, renewable energy to their customers. The Companies’ firm power generating units are needed to support intermittent, as-available, renewable generation (such as wind or PV) on their respective systems. Power systems require that the generation resources collectively provide characteristics that the systems fundamentally need for reliable operation. These characteristics include adequate firm generating capacity, controlled dispatch of generation, frequency regulation and sufficient rotational inertia to maintain system stability. Base load, cycling and peaking generating units are commonly referred to as “firm” power and their power output can be dispatched as needed. These forms of “conventional generation,” to the extent that they are fully dispatchable from minimum to full load by the utility, are capable of load- following and also provide frequency control and voltage support to the systems. By contrast. as-available resources (such as wind and PV) are not firm, cannot be dispatched and are unable to provide prescribed amounts of power upon command or at scheduled times.

It is apparent after reviewing all of the Scenarios that there is no single renewable resource technology that will enable the Hawaiian Electric Companies to comply with the requirements of the RPS law. The results of this analysis support the Hawaiian Electric Companies’ two-pronged strategy for meeting and hopefully exceeding the RPS requirements. The first prong of the strategy is developing and procuring a diversity of renewable energy resources, including wind, solar power, biofuels, geothermal and possibly other types of renewable generation (e.g., OTEC and wave energy) that may become viable over the next several years. The second prong of the strategy involves using biofuels in the Companies’ existing generating units in order to ensure that the Companies can meet the RPS. Biofuels are a critical component ofa “green” energy future for the Companies because using biofuels in the existing conventional generating units will allow for the units to continue to provide the essential grid services including load following, frequency response, voltage control, and on-line operating and spinning reserves without having to rely solely on fossil fuels to do so. Considering the amount of energy that Big Wind could contribute to the Companies meeting the RPS, and the relative cost of the project relative to other renewable options, it is prudent for Hawaiian Electric to continue to support and implement its development.

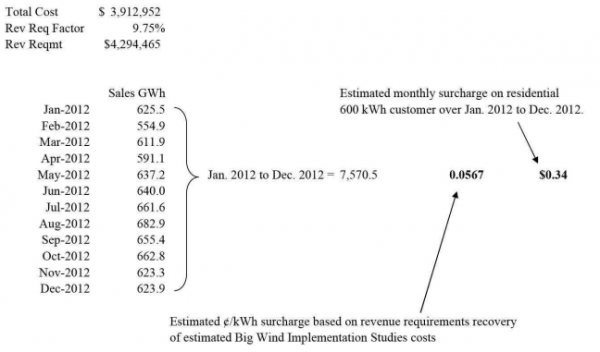

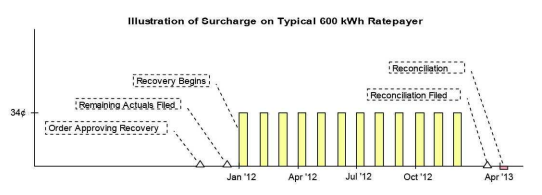

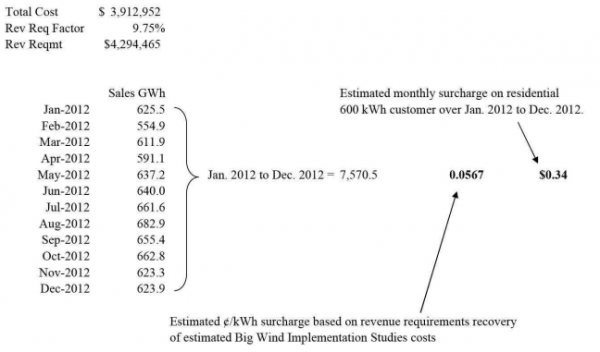

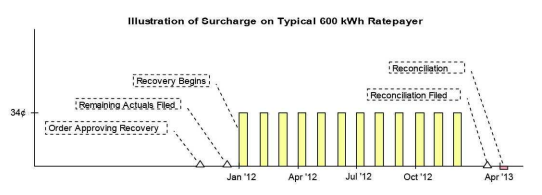

Big Wind Implementation Studies Estimated Surcharge Calculation

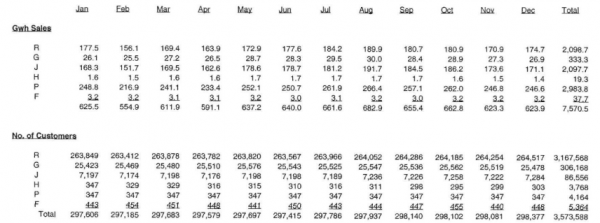

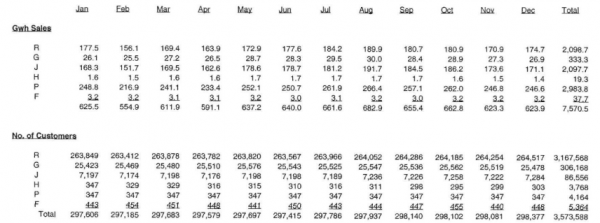

Hawaiian Electric Co

2012 Revenue Forcast Update – May 2010 Sales Forecast (with DSM)

GWH Sales and No of Customers

FOOTNOTES

1. As defined in the body of the Request, “Big Wind” refers to the large amounts of wind-generated renewable

energy potentially located on the islands of Lanai and/or Molokai.

2. The “capacity factor” is typically defined as the actual energy that a plant can produce for a given time period divided by its potential energy output if able to operate at its maximum nameplate capacity over the same time period. Annual variations in the capacity factor of a plant naturally occur as a result of variables such as weather

driven changes in available wind or solar irradiance at the plant site and plant availability (e.g., plant equipment maintenance and forced outages

3. The “net capacity factor” represents the actual energy delivered by a plant to the grid over a given period of time (as limited by the amount of energy that the system can actually accommodate) divided by its potential energy output if able to operate at its maximum nameplate capacity over the same time period. Thus, the net capacity factor

of a plant is further reduced as more potential energy production is curtailed due to the limited capability of the system to accept the energy. For example, when system energy demand is at its lowest in the late evening to early moming hours, the system will not always be able to accept all of the wind energy that a 400 MW wind plant may

be able to produce during those hours, resulting in excess energy curtailment of the wind plant.

4. The LCOE equation calculates a unit’s electricity generation cost in $/kWh accounting for the investment/capital costs, O&M and fuel costs (if any) over its lifetime. It provides a common basis for comparing different technologies with different capacities and lifetimes.

5. Slide #2 of NREL’s May 2010 presentation contained the following confidentiality provision: “This presentation is intended for members of the OWITS TRC, and all confidentiality and NDA agreements apply to information contained in this presentation. Not for distribution outside of the TRC.” Although the presentation has not been

reproduced and included among the exhibits to the Company’s instant Request, the Commission staff, Consumer Advocate staff, and other TRC members were privy to the presentation by virtue of their TRC membership.

6. See Docket No. 2010-0080, HECO T-8 at 74.

7. In 2020, 2,762 GWh of renewable generation energy will be required to meet the 25% RPS based on forecasted Hawaiian Electric sales of 11,047 GWh. In 2030, 4,866 GWh of renewable generation energy will be required to meet the 40% RPS based on forecasted Hawaiian Electric sales of 12,164 GWh.

8. See page 24 of Hawaiian Electric’s Letter from D. Endo-Omoto to the Commission dated April 29, 2010 regarding Docket No. 2008-0273 -FIT Proceeding, Schedule FIT Tier 3 Tariffs and Agreement.

9. 23.60/kWh is the price (levehzed over 20 years) for Tier 3 PV > 500 kW and < the lesser of 5 MW or 1% of the

system peak load (if the seller provides written documentation by the in-service date that the seller will elect the 24.5% tax credit refund provision for solar energy technologies as provided in the Hawaii state tax code, HRS § 235-12.5) included in the proposed Schedule FIT Tariff- Tier 3 – Oahu, filed by the Companies on April 29, 2010 in Docket No. 2008-0273. An alternative price of 19.70/kWh is available to sellers who elect to take the 35% Hawaii state renewable energy tax credit as also prescribed in the state tax code. However, to date, all of the sellers have elected to take the 24.5% refundable credit rather than the 35% credit – due apparently to difficulties in monetizing the 35% credit. Additional discussion regarding this issue is provided on page 5 of the letter filed by the

Companies in the FIT proceeding on January 7, 2010. The Companies do not know what will happen with respect to solar tax credits/rebates or FIT Tier 3 pricing in the future, and any new developments could impact the future cost of PV generation.

10 PV installations produce the most energy with unobstructed views of the sun and when orientated to maximize the time they face the sun. It is unreasonable to assume that every rooftop will have 100% unobstructed views of the sun considering shade from trees, mountains and buildings, as well as cloud cover. All of these factors reduce the

actual energy produced from the system.

11. See Hawaiian Electric’s application filed on March 9, 2011 in Docket No. 2011-0051. Because the new location offered a shghtly lower estimated interconnection cost, Hawaiian Electric and Kalaeloa Solar negotiated a reduced price of $ 191.14/MWh for the first year. The price escalates at 3% per year for the next 11 years, reduces the year

13 price to $211.84/MWh and eliminates further annual escalation for the remainder of the term. This equates to a levelized price of 21.80/kWh. See id.. Appendix 8 at 1-2.

12. See Hawaiian Electric’s application fded on January 19, 2011 in Docket No. 2011-0015. Based on the stepped pricing structure that was agreed upon between Hawaiian Electric and IC Sunshine, the price for each MWh of energy in the first year will be $210.00 per MWh. The price will escalate at 1.5% for the next 14 years until it reaches $258.67 per MWTi in year 15 of the contract. In year 16, the price per MWh will decrease by about 23% to $200.00 per MWh. For the remaining term of the PPA, the energy price will remain at $200.00 for each MWh of delivered energy. See Exhibit 7 to Hawaiian Electric’s letter to the Commission filed on January 9, 2011 in Docket No. 2011-0015 at 5.

Hawaiian Electric has worked with its consultant, Papay Quayle Resources, LLC to conduct an economic sensitivity analysis of the cost of Big Wind. As summarized in Table 3, for 1,480 GWh per year of wind energy delivered to Oahu (42% net capacity factor), the LCOE values derived in that analysis are summarized for various Big Wind project components based on the assumptions listed below.

Hawaiian Electric has worked with its consultant, Papay Quayle Resources, LLC to conduct an economic sensitivity analysis of the cost of Big Wind. As summarized in Table 3, for 1,480 GWh per year of wind energy delivered to Oahu (42% net capacity factor), the LCOE values derived in that analysis are summarized for various Big Wind project components based on the assumptions listed below.

The RPS scenario mialysis also demonstrates how using renewable energy generated from biofuels can be an important element to make up any shortfalls in meeting the RPS targets. While the exact amount of biofuels that will be needed is uncertain, Hawaiian Electric’s planned conversion of its Kahe generating units to bum bio-crude blends will provide essential flexibility to address RPS renewable generation energy shortfalls which may arise if any of the numerous renewable energy resources or projects are delayed or do not materialize.

Integrating renewable and sustainable biofuels into a portion of the Companies’ existing generating systems is an important part of the Companies’ renewable energy strategy of delivering clean, renewable energy to their customers. The Companies’ firm power generating units are needed to support intermittent, as-available, renewable generation (such as wind or PV) on their respective systems. Power systems require that the generation resources collectively provide characteristics that the systems fundamentally need for reliable operation. These characteristics include adequate firm generating capacity, controlled dispatch of generation, frequency regulation and sufficient rotational inertia to maintain system stability. Base load, cycling and peaking generating units are commonly referred to as “firm” power and their power output can be dispatched as needed. These forms of “conventional generation,” to the extent that they are fully dispatchable from minimum to full load by the utility, are capable of load- following and also provide frequency control and voltage support to the systems. By contrast. as-available resources (such as wind and PV) are not firm, cannot be dispatched and are unable to provide prescribed amounts of power upon command or at scheduled times.

It is apparent after reviewing all of the Scenarios that there is no single renewable resource technology that will enable the Hawaiian Electric Companies to comply with the requirements of the RPS law. The results of this analysis support the Hawaiian Electric Companies’ two-pronged strategy for meeting and hopefully exceeding the RPS requirements. The first prong of the strategy is developing and procuring a diversity of renewable energy resources, including wind, solar power, biofuels, geothermal and possibly other types of renewable generation (e.g., OTEC and wave energy) that may become viable over the next several years. The second prong of the strategy involves using biofuels in the Companies’ existing generating units in order to ensure that the Companies can meet the RPS. Biofuels are a critical component ofa “green” energy future for the Companies because using biofuels in the existing conventional generating units will allow for the units to continue to provide the essential grid services including load following, frequency response, voltage control, and on-line operating and spinning reserves without having to rely solely on fossil fuels to do so. Considering the amount of energy that Big Wind could contribute to the Companies meeting the RPS, and the relative cost of the project relative to other renewable options, it is prudent for Hawaiian Electric to continue to support and implement its development.

Big Wind Implementation Studies Estimated Surcharge Calculation

The RPS scenario mialysis also demonstrates how using renewable energy generated from biofuels can be an important element to make up any shortfalls in meeting the RPS targets. While the exact amount of biofuels that will be needed is uncertain, Hawaiian Electric’s planned conversion of its Kahe generating units to bum bio-crude blends will provide essential flexibility to address RPS renewable generation energy shortfalls which may arise if any of the numerous renewable energy resources or projects are delayed or do not materialize.

Integrating renewable and sustainable biofuels into a portion of the Companies’ existing generating systems is an important part of the Companies’ renewable energy strategy of delivering clean, renewable energy to their customers. The Companies’ firm power generating units are needed to support intermittent, as-available, renewable generation (such as wind or PV) on their respective systems. Power systems require that the generation resources collectively provide characteristics that the systems fundamentally need for reliable operation. These characteristics include adequate firm generating capacity, controlled dispatch of generation, frequency regulation and sufficient rotational inertia to maintain system stability. Base load, cycling and peaking generating units are commonly referred to as “firm” power and their power output can be dispatched as needed. These forms of “conventional generation,” to the extent that they are fully dispatchable from minimum to full load by the utility, are capable of load- following and also provide frequency control and voltage support to the systems. By contrast. as-available resources (such as wind and PV) are not firm, cannot be dispatched and are unable to provide prescribed amounts of power upon command or at scheduled times.

It is apparent after reviewing all of the Scenarios that there is no single renewable resource technology that will enable the Hawaiian Electric Companies to comply with the requirements of the RPS law. The results of this analysis support the Hawaiian Electric Companies’ two-pronged strategy for meeting and hopefully exceeding the RPS requirements. The first prong of the strategy is developing and procuring a diversity of renewable energy resources, including wind, solar power, biofuels, geothermal and possibly other types of renewable generation (e.g., OTEC and wave energy) that may become viable over the next several years. The second prong of the strategy involves using biofuels in the Companies’ existing generating units in order to ensure that the Companies can meet the RPS. Biofuels are a critical component ofa “green” energy future for the Companies because using biofuels in the existing conventional generating units will allow for the units to continue to provide the essential grid services including load following, frequency response, voltage control, and on-line operating and spinning reserves without having to rely solely on fossil fuels to do so. Considering the amount of energy that Big Wind could contribute to the Companies meeting the RPS, and the relative cost of the project relative to other renewable options, it is prudent for Hawaiian Electric to continue to support and implement its development.

Big Wind Implementation Studies Estimated Surcharge Calculation

FOOTNOTES

1. As defined in the body of the Request, “Big Wind” refers to the large amounts of wind-generated renewable

energy potentially located on the islands of Lanai and/or Molokai.

2. The “capacity factor” is typically defined as the actual energy that a plant can produce for a given time period divided by its potential energy output if able to operate at its maximum nameplate capacity over the same time period. Annual variations in the capacity factor of a plant naturally occur as a result of variables such as weather

driven changes in available wind or solar irradiance at the plant site and plant availability (e.g., plant equipment maintenance and forced outages

3. The “net capacity factor” represents the actual energy delivered by a plant to the grid over a given period of time (as limited by the amount of energy that the system can actually accommodate) divided by its potential energy output if able to operate at its maximum nameplate capacity over the same time period. Thus, the net capacity factor

of a plant is further reduced as more potential energy production is curtailed due to the limited capability of the system to accept the energy. For example, when system energy demand is at its lowest in the late evening to early moming hours, the system will not always be able to accept all of the wind energy that a 400 MW wind plant may

be able to produce during those hours, resulting in excess energy curtailment of the wind plant.

4. The LCOE equation calculates a unit’s electricity generation cost in $/kWh accounting for the investment/capital costs, O&M and fuel costs (if any) over its lifetime. It provides a common basis for comparing different technologies with different capacities and lifetimes.

5. Slide #2 of NREL’s May 2010 presentation contained the following confidentiality provision: “This presentation is intended for members of the OWITS TRC, and all confidentiality and NDA agreements apply to information contained in this presentation. Not for distribution outside of the TRC.” Although the presentation has not been

reproduced and included among the exhibits to the Company’s instant Request, the Commission staff, Consumer Advocate staff, and other TRC members were privy to the presentation by virtue of their TRC membership.

6. See Docket No. 2010-0080, HECO T-8 at 74.

7. In 2020, 2,762 GWh of renewable generation energy will be required to meet the 25% RPS based on forecasted Hawaiian Electric sales of 11,047 GWh. In 2030, 4,866 GWh of renewable generation energy will be required to meet the 40% RPS based on forecasted Hawaiian Electric sales of 12,164 GWh.

8. See page 24 of Hawaiian Electric’s Letter from D. Endo-Omoto to the Commission dated April 29, 2010 regarding Docket No. 2008-0273 -FIT Proceeding, Schedule FIT Tier 3 Tariffs and Agreement.

9. 23.60/kWh is the price (levehzed over 20 years) for Tier 3 PV > 500 kW and < the lesser of 5 MW or 1% of the

system peak load (if the seller provides written documentation by the in-service date that the seller will elect the 24.5% tax credit refund provision for solar energy technologies as provided in the Hawaii state tax code, HRS § 235-12.5) included in the proposed Schedule FIT Tariff- Tier 3 – Oahu, filed by the Companies on April 29, 2010 in Docket No. 2008-0273. An alternative price of 19.70/kWh is available to sellers who elect to take the 35% Hawaii state renewable energy tax credit as also prescribed in the state tax code. However, to date, all of the sellers have elected to take the 24.5% refundable credit rather than the 35% credit – due apparently to difficulties in monetizing the 35% credit. Additional discussion regarding this issue is provided on page 5 of the letter filed by the

Companies in the FIT proceeding on January 7, 2010. The Companies do not know what will happen with respect to solar tax credits/rebates or FIT Tier 3 pricing in the future, and any new developments could impact the future cost of PV generation.

10 PV installations produce the most energy with unobstructed views of the sun and when orientated to maximize the time they face the sun. It is unreasonable to assume that every rooftop will have 100% unobstructed views of the sun considering shade from trees, mountains and buildings, as well as cloud cover. All of these factors reduce the

actual energy produced from the system.

11. See Hawaiian Electric’s application filed on March 9, 2011 in Docket No. 2011-0051. Because the new location offered a shghtly lower estimated interconnection cost, Hawaiian Electric and Kalaeloa Solar negotiated a reduced price of $ 191.14/MWh for the first year. The price escalates at 3% per year for the next 11 years, reduces the year

13 price to $211.84/MWh and eliminates further annual escalation for the remainder of the term. This equates to a levelized price of 21.80/kWh. See id.. Appendix 8 at 1-2.

12. See Hawaiian Electric’s application fded on January 19, 2011 in Docket No. 2011-0015. Based on the stepped pricing structure that was agreed upon between Hawaiian Electric and IC Sunshine, the price for each MWh of energy in the first year will be $210.00 per MWh. The price will escalate at 1.5% for the next 14 years until it reaches $258.67 per MWTi in year 15 of the contract. In year 16, the price per MWh will decrease by about 23% to $200.00 per MWh. For the remaining term of the PPA, the energy price will remain at $200.00 for each MWh of delivered energy. See Exhibit 7 to Hawaiian Electric’s letter to the Commission filed on January 9, 2011 in Docket No. 2011-0015 at 5.

FOOTNOTES

1. As defined in the body of the Request, “Big Wind” refers to the large amounts of wind-generated renewable

energy potentially located on the islands of Lanai and/or Molokai.

2. The “capacity factor” is typically defined as the actual energy that a plant can produce for a given time period divided by its potential energy output if able to operate at its maximum nameplate capacity over the same time period. Annual variations in the capacity factor of a plant naturally occur as a result of variables such as weather

driven changes in available wind or solar irradiance at the plant site and plant availability (e.g., plant equipment maintenance and forced outages

3. The “net capacity factor” represents the actual energy delivered by a plant to the grid over a given period of time (as limited by the amount of energy that the system can actually accommodate) divided by its potential energy output if able to operate at its maximum nameplate capacity over the same time period. Thus, the net capacity factor

of a plant is further reduced as more potential energy production is curtailed due to the limited capability of the system to accept the energy. For example, when system energy demand is at its lowest in the late evening to early moming hours, the system will not always be able to accept all of the wind energy that a 400 MW wind plant may

be able to produce during those hours, resulting in excess energy curtailment of the wind plant.

4. The LCOE equation calculates a unit’s electricity generation cost in $/kWh accounting for the investment/capital costs, O&M and fuel costs (if any) over its lifetime. It provides a common basis for comparing different technologies with different capacities and lifetimes.

5. Slide #2 of NREL’s May 2010 presentation contained the following confidentiality provision: “This presentation is intended for members of the OWITS TRC, and all confidentiality and NDA agreements apply to information contained in this presentation. Not for distribution outside of the TRC.” Although the presentation has not been

reproduced and included among the exhibits to the Company’s instant Request, the Commission staff, Consumer Advocate staff, and other TRC members were privy to the presentation by virtue of their TRC membership.

6. See Docket No. 2010-0080, HECO T-8 at 74.

7. In 2020, 2,762 GWh of renewable generation energy will be required to meet the 25% RPS based on forecasted Hawaiian Electric sales of 11,047 GWh. In 2030, 4,866 GWh of renewable generation energy will be required to meet the 40% RPS based on forecasted Hawaiian Electric sales of 12,164 GWh.

8. See page 24 of Hawaiian Electric’s Letter from D. Endo-Omoto to the Commission dated April 29, 2010 regarding Docket No. 2008-0273 -FIT Proceeding, Schedule FIT Tier 3 Tariffs and Agreement.

9. 23.60/kWh is the price (levehzed over 20 years) for Tier 3 PV > 500 kW and < the lesser of 5 MW or 1% of the

system peak load (if the seller provides written documentation by the in-service date that the seller will elect the 24.5% tax credit refund provision for solar energy technologies as provided in the Hawaii state tax code, HRS § 235-12.5) included in the proposed Schedule FIT Tariff- Tier 3 – Oahu, filed by the Companies on April 29, 2010 in Docket No. 2008-0273. An alternative price of 19.70/kWh is available to sellers who elect to take the 35% Hawaii state renewable energy tax credit as also prescribed in the state tax code. However, to date, all of the sellers have elected to take the 24.5% refundable credit rather than the 35% credit – due apparently to difficulties in monetizing the 35% credit. Additional discussion regarding this issue is provided on page 5 of the letter filed by the

Companies in the FIT proceeding on January 7, 2010. The Companies do not know what will happen with respect to solar tax credits/rebates or FIT Tier 3 pricing in the future, and any new developments could impact the future cost of PV generation.

10 PV installations produce the most energy with unobstructed views of the sun and when orientated to maximize the time they face the sun. It is unreasonable to assume that every rooftop will have 100% unobstructed views of the sun considering shade from trees, mountains and buildings, as well as cloud cover. All of these factors reduce the

actual energy produced from the system.

11. See Hawaiian Electric’s application filed on March 9, 2011 in Docket No. 2011-0051. Because the new location offered a shghtly lower estimated interconnection cost, Hawaiian Electric and Kalaeloa Solar negotiated a reduced price of $ 191.14/MWh for the first year. The price escalates at 3% per year for the next 11 years, reduces the year

13 price to $211.84/MWh and eliminates further annual escalation for the remainder of the term. This equates to a levelized price of 21.80/kWh. See id.. Appendix 8 at 1-2.

12. See Hawaiian Electric’s application fded on January 19, 2011 in Docket No. 2011-0015. Based on the stepped pricing structure that was agreed upon between Hawaiian Electric and IC Sunshine, the price for each MWh of energy in the first year will be $210.00 per MWh. The price will escalate at 1.5% for the next 14 years until it reaches $258.67 per MWTi in year 15 of the contract. In year 16, the price per MWh will decrease by about 23% to $200.00 per MWh. For the remaining term of the PPA, the energy price will remain at $200.00 for each MWh of delivered energy. See Exhibit 7 to Hawaiian Electric’s letter to the Commission filed on January 9, 2011 in Docket No. 2011-0015 at 5.